Our team completely rebuilt this 800-ton Danly 4-point stamping press. We disassembled, cleaned, and inspected each press component to ensure proper repairs were made. We manufactured new tie rod nuts, adjustment nuts, worm gears, worm shafts, slide adjust bearing retainers, slide adjust shafts, and eccentric pins.

Our Machinists machined the bed, bolster and slide flat and parallel, and repaired the damaged T-slots in the slide face and bolster face to allow proper die connection. Our welders repaired cracks in the slide, and eccentric gears.

Our Engineers designed a new metered lubrication system utilizing the existing reservoir and drainage systems and worked with outside contractors to install the press pit, support frame and floor plating.

Our technicians installed new divider valves, lubrication lines and hoses, as well as a new recirculating pump, filters, gauges, and cycle switches. Our electricians stripped out the old wiring and wired new control panels with PLC programed to work with the new metered lubrication system and upgraded the motor, brake monitor, and tonnage monitor. Our team assisted in assembling the press and leveling the press and performed tests to ensure the press and all safety systems were running properly.

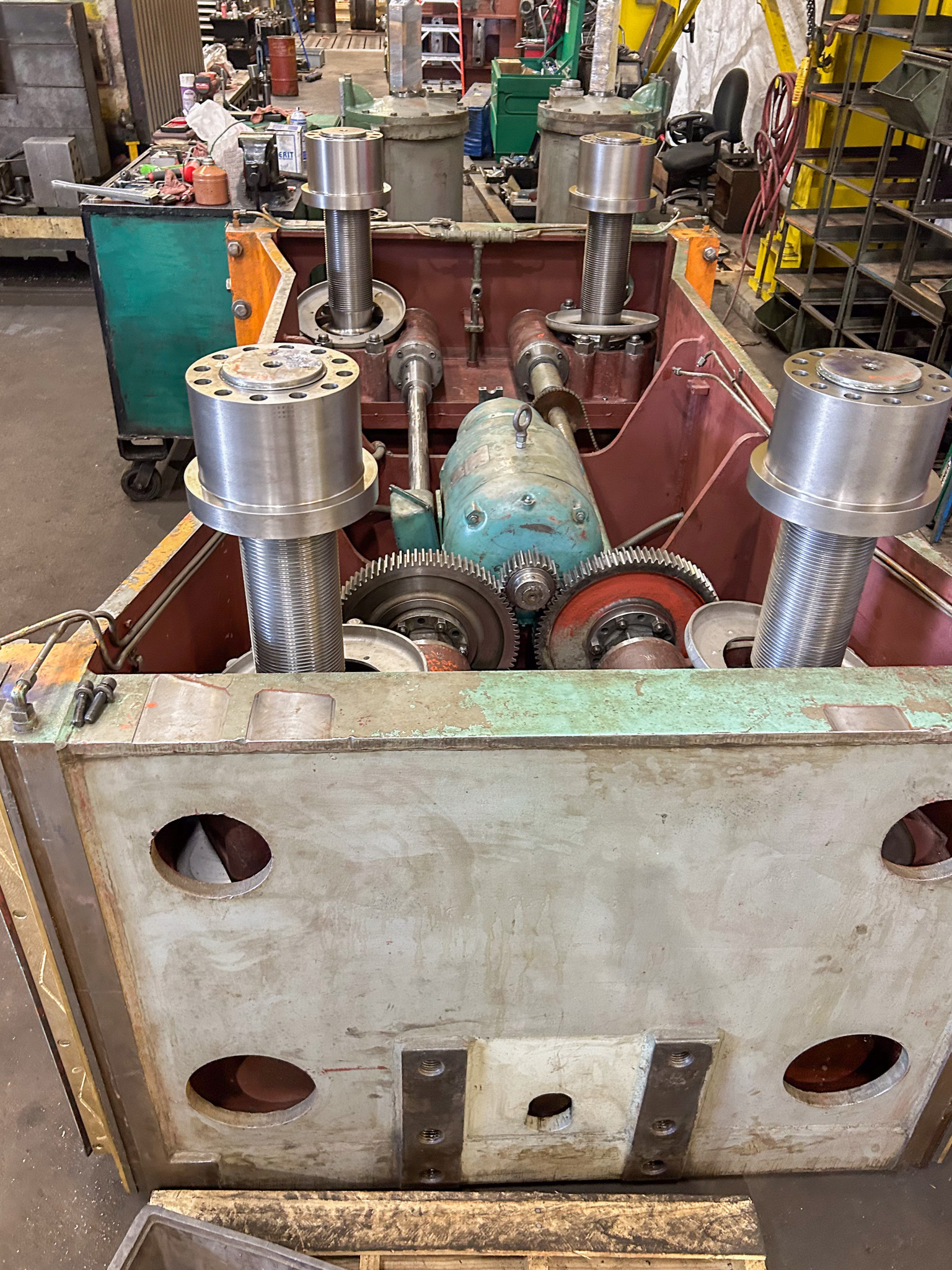

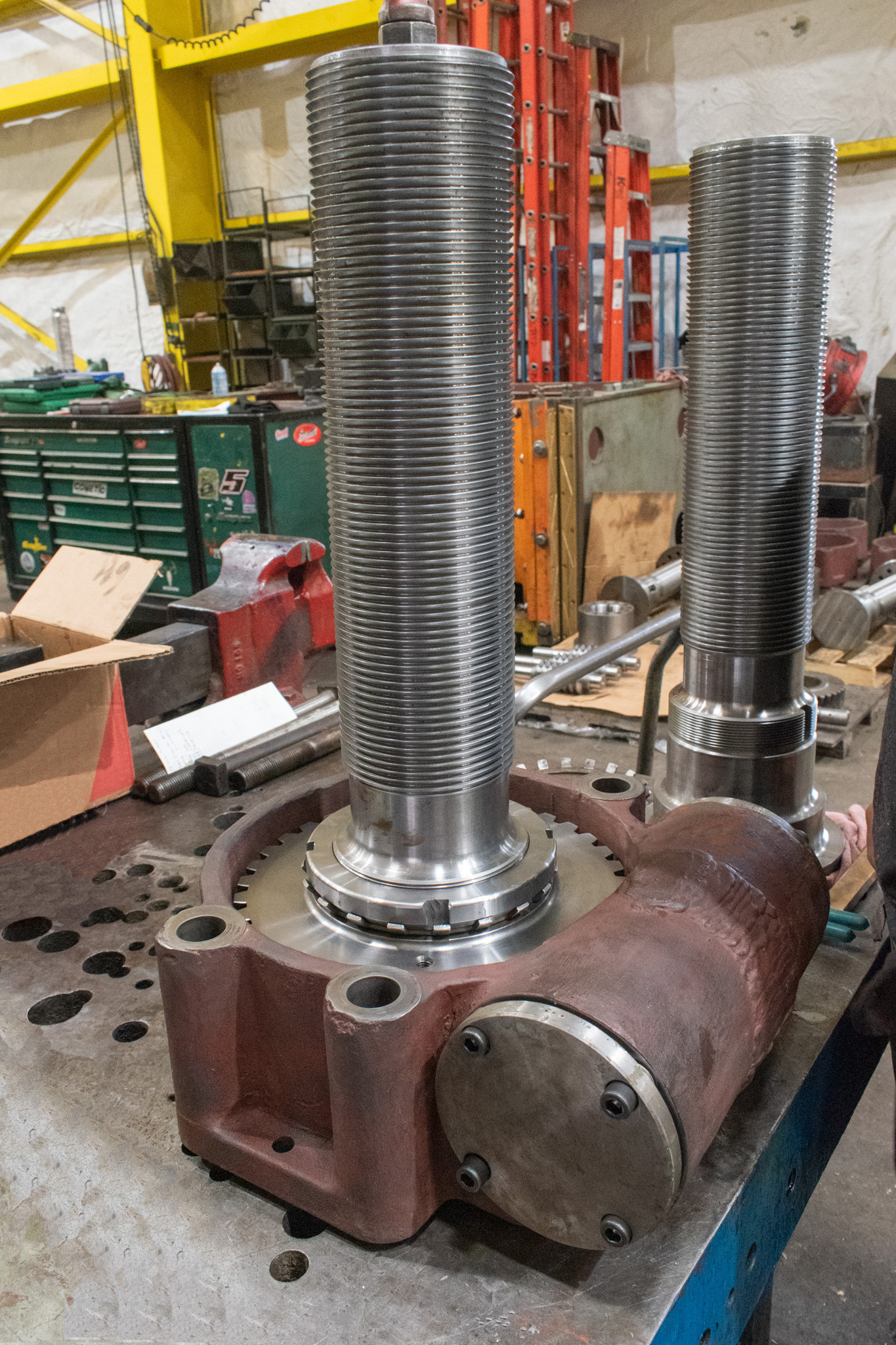

- Crown Before Repairs

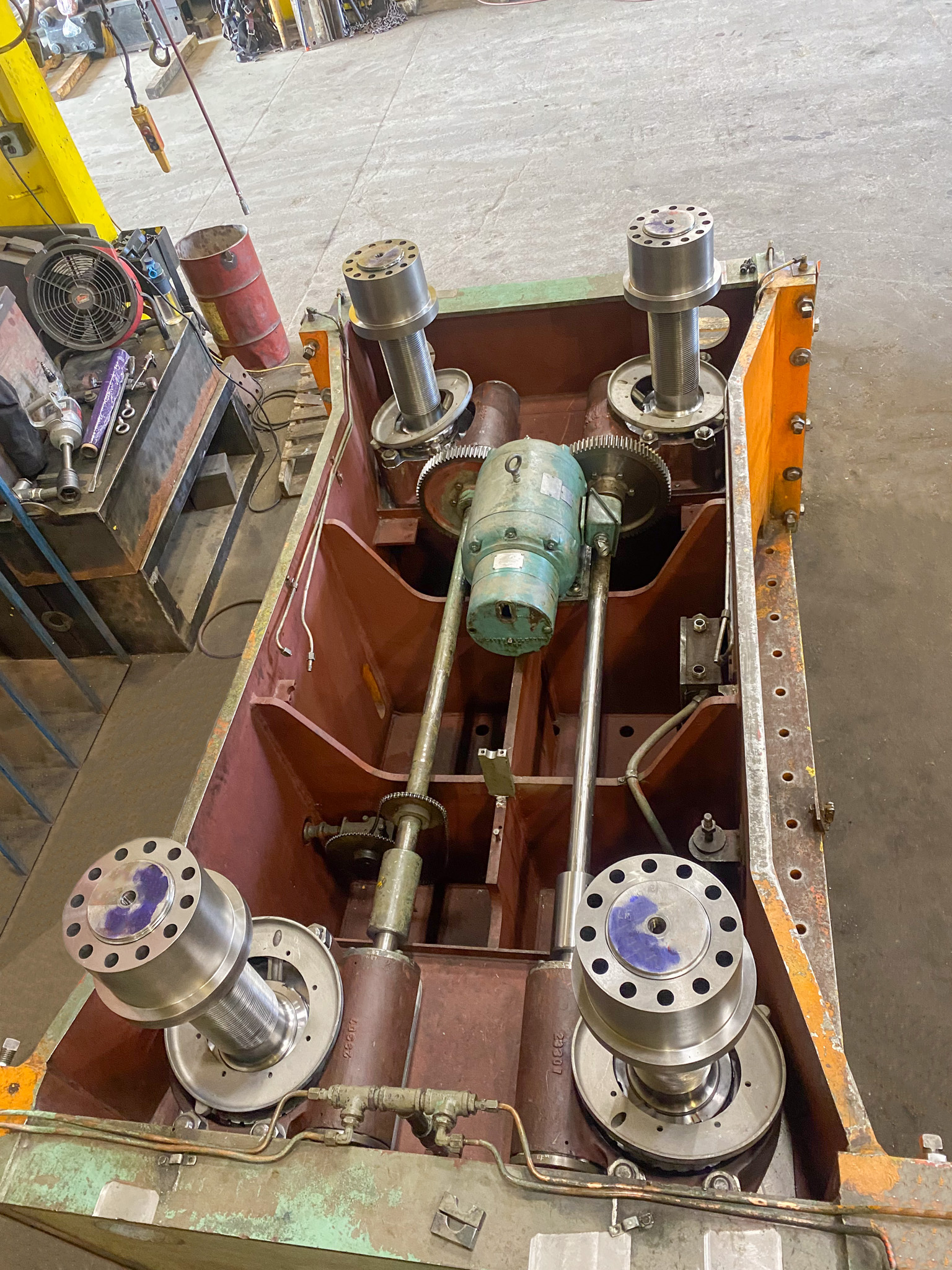

- Crown After Repairs

- Electrical Panel Before Repairs

- Electrical Panel After Repairs

- Slide Before Repairs

- Slide After Repairs

- Bolster Before Repairs

- Bolster After Repairs