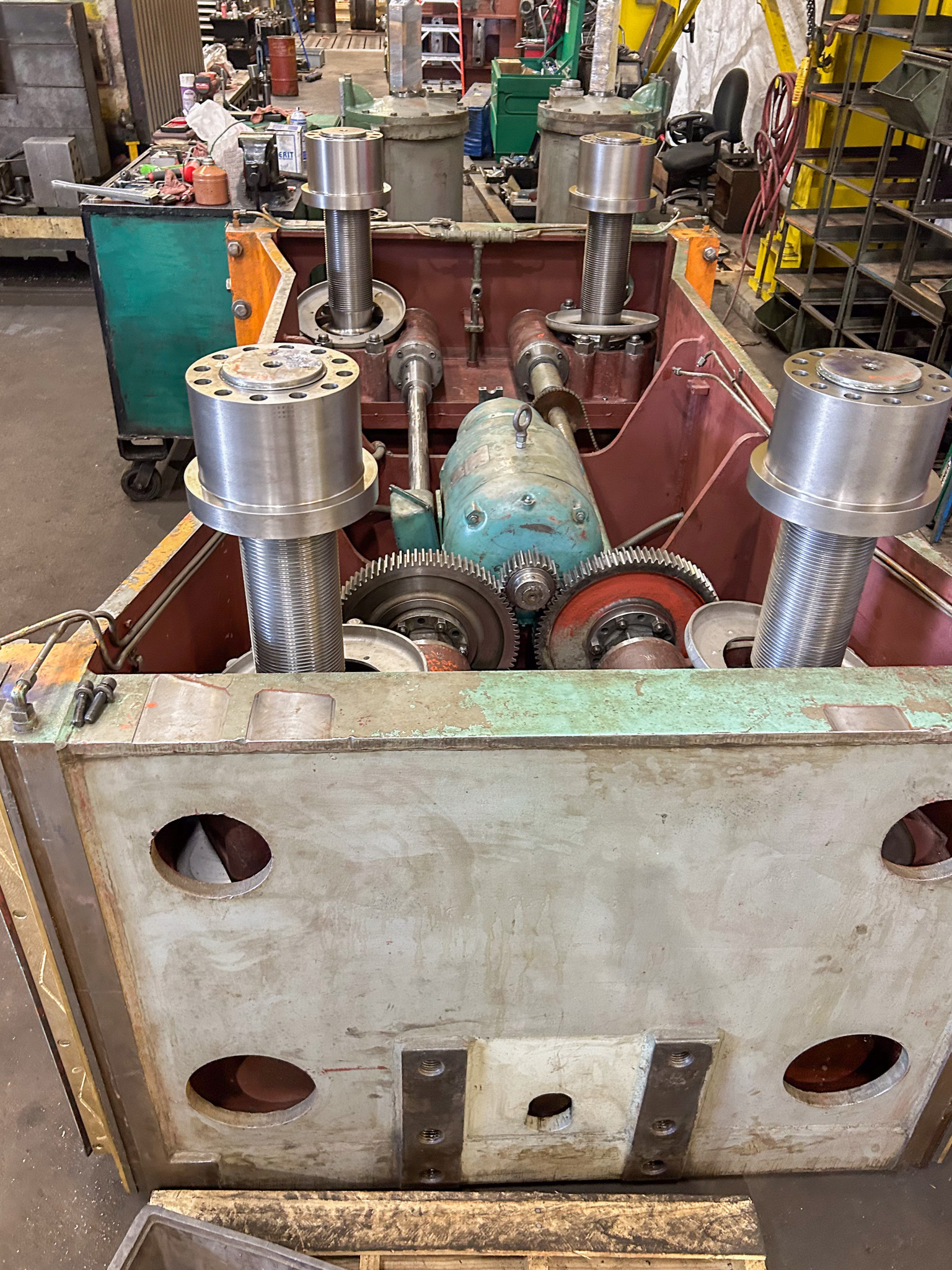

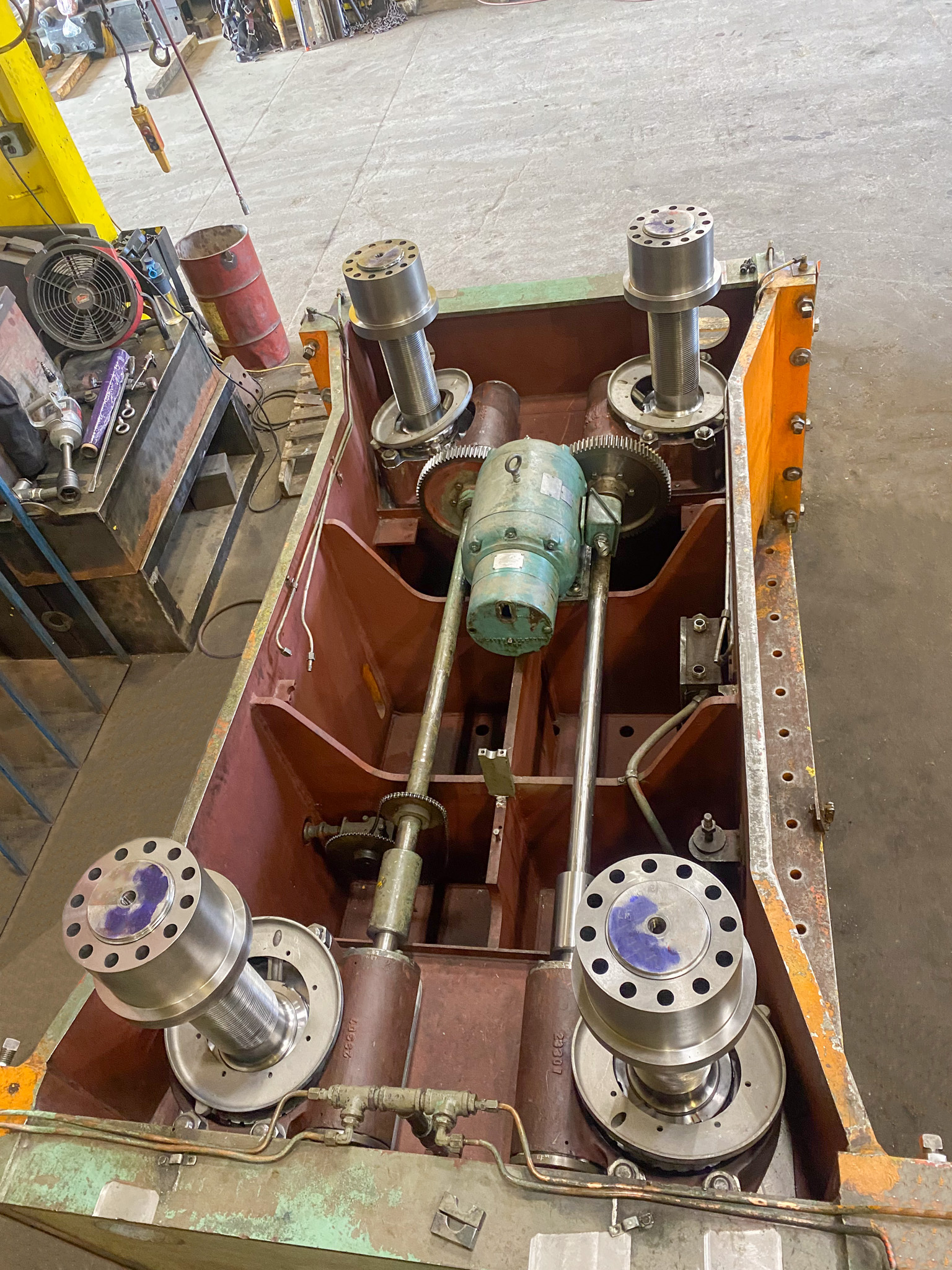

Our customer had two slide adjust nuts suffer catastrophic failure when they broke in half during production. When our team pulled the slide out, they found the threads from the nuts had sheared off and wrapped around the screws and in the nut housing. The screws had damage to the threads and metal shavings and oil had collected in the housing. Our team inspected the rest of the press and found the damage was contained to the slide adjustment components.

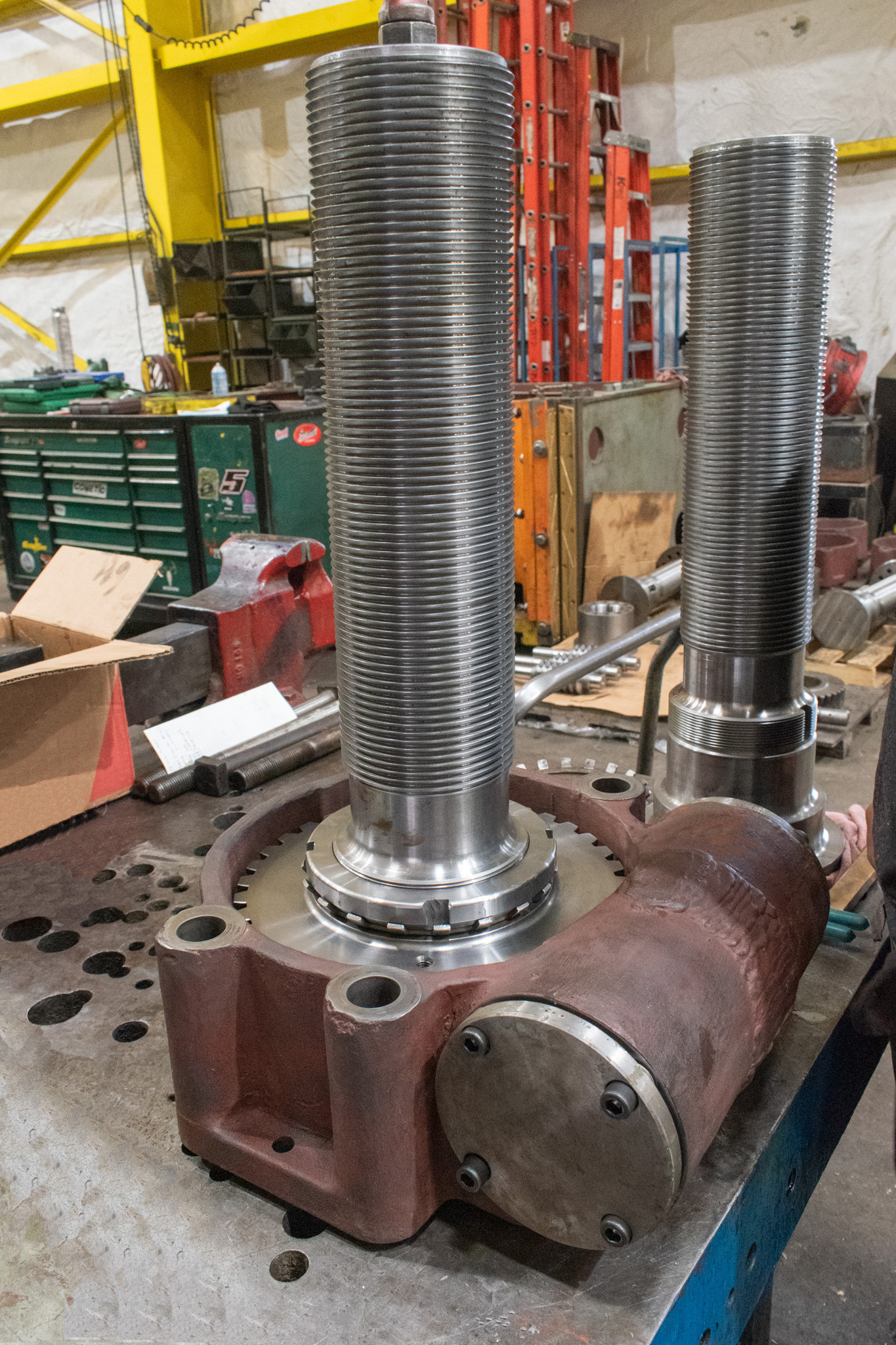

With the slide back at our facility we were able to manufacture four new adjustment screws and four new adjustment nuts. Additionally, our team cleaned out and repainted the slide adjustment barrels, cleaned, and repainted the inside of the slide, replaced the worm gears and worm shafts, machined the bottom of the slide flat, and reassembled the adjustment components back into the slide. Once all work was complete, we transported the slide back to our customer’s facility and installed the slide back into the press.